5th class feeder boiler for burning eco-pea coal

To download

Feeder boiler Q EKO GL – automatic boiler for coal combustion. The structure is basedd on a Heiztechnik flame heat exchanger. The boiler is equipped with a cast-iron retort burner with an integrated worm fuel feeder. The combustion process is controlled by weather automatics with HTLogic III autoregulation for easy and simple operation.

Optimisation of the combustion chamber made it possible to achieve low emissions of pollutants and high thermal efficiency of the boiler. The boiler is equipped with a cast iron retort burner with an integrated worm fuel feeder. The boiler is equipped with HT-tronic® 700 weather-compensated automatics with a mixing valve, central heating pump and DHW pump. It allows additional mixing valve modules and an internet module to be connected. The automatics can work in HT Logic system which automatically adjusts working parameters and modulates the boiler power according to the fuel and boiler temperature. Automatic control systems enable protection of the return temperature by controlling the boiler pump and enable connection of room thermostats. The boiler can be equipped with an automatic ash removal system and a sensor for feeder rotation control. The boilers can be made with a built-in cooling coil and enlarged fuel tank. The boilers meet the requirements for environmental protection of the 5th class (the highest) established in the PN-EN 303-5:2012 standard. The boilers are certified by the “Polskie Ciepło” programme.

NEW Boiler can be equipped with OPS module – LAMBDA PLUS combustion optimizer.

| Rated power | kW | 15 | 20 | 24 | 30 | 40 | 50 | 60 | 69 |

| Power range | kW | 5-15 | 6-20 | 8-24 | 9-30 | 12-40 | 15-50 | 18-60 | 21-69 |

| Max. working temperature | oC | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 85 |

| Water capacity | L | 90 | 104 | 104 | 140 | 150 | 160 | 170 | 180 |

| Max working pressure | Bar | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| Min. flue draught | Pa | 15 | 20 | 20 | 23 | 26 | 30 | 34 | 36 |

| Technological connection | “ | 1 1/2 | 1 1/2 | 1 1/2 | 1 1/2 | 1 1/2 | 1 1/2 | 2 | 2 |

| Flue connection | mm | 150 | 150 | 150 | 150 | 150 | 200 | 200 | 200 |

| Boiler weight | kg | 477 | 522 | 554 | 575 | 595 | 700 | 780 | 860 |

| Tank volume | dm3 | 225 | 225 | 225 | 300 | 300 | 300 | 775 | 775 |

| Extended hopper volume | dm3 | 300 / 500 | 300 / 500 | 300 / 500 | 500 | 500 | 500 | – | – |

| Width of set | cm | 113 | 113 | 113 | 122 | 122 | 157 | 157 | 157 |

| Boiler width | cm | 54 | 54 | 54 | 70 | 70 | 70 | 70 | 70 |

| Tank width | cm | 59 | 59 | 59 | 52 | 52 | 52 | 87 | 87 |

| Extended tank width 300 | cm | 52 | 52 | 52 | – | – | – | – | – |

| Extended tank width 500 | cm | 83 | 83 | 83 | 83 | 83 | 83 | – | – |

| Depth of body with high flue | cm | 76 | 86 | 96 | 86 | 90 | 92 | 102 | 112 |

| Body height | cm | 154 | 154 | 154 | 154 | 154 | 182 | 182 | 182 |

| Supply spigot height* | cm | 150 | 150 | 150 | 150 | 150 | 171 | 171 | 171 |

| Height to flue centre* | cm | 131 | 131 | 131 | 131 | 131 | 152 | 152 | 152 |

| Height of return spigot | cm | 37 | 37 | 37 | 37 | 37 | 60 | 60 | 60 |

| Depth of body with flue outlet upwards | cm | 86 | 96 | 106 | 95 | 100 | 107 | 116 | 126 |

| Height of the flue with flue outlet upwards | cm | 145 | 145 | 145 | 145 | 145 | 167 | 167 | 167 |

* – Not applicable to boilers with flue gas leading upwards

-

Boiler pump

-

CH pump

-

DHW pump

-

Mixing valve pump

-

Mixing valve

-

Weather-compensated control

-

Thermostat

-

HT Logic II

-

Alarm

-

WWW module

-

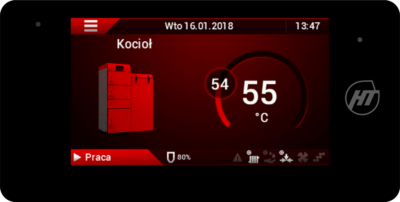

Colour display

-

Touch screen display

Automation extension modules

- Valve module,

- Valve pump,

- Mixing valve,

- Weather-compensated control,

- Thermostat,

- Buffer pump,

- Circulation pump,

- Wired remote control panel with room thermostat,

- Wireless remote control panel with room thermostat,

- Room thermostat – wired,

- Room thermostat, wireless with weekly programme,

- Room thermostat with a weekly programme – directly with a wireless APP mobile application,

- Internet module – operated via a web browser and mobile application,

- Combustion optimiser with Eko Lambda probe,

-

Boiler pump

-

CH pump

-

DHW pump

-

Mixing valve pump

-

Mixing valve

-

Weather-compensated control

-

Thermostat

-

HT Logic II

-

Alarm

-

Colour display

-

WWW module

Automation extension modules

- Valve module,

- Valve pump,

- Mixing valve,

- Weather-compensated control,

- Thermostat,

- Buffer pump,

- Circulation pump,

- Wired remote control panel with room thermostat,

- Wireless remote control panel with room thermostat,

- Room thermostat – wired,

- Room thermostat, wireless with weekly programme,

- Room thermostat with a weekly programme – directly with a wireless APP mobile application,

- Internet module – operated via a web browser and mobile application,

- Combustion optimiser with Eko Lambda probe,