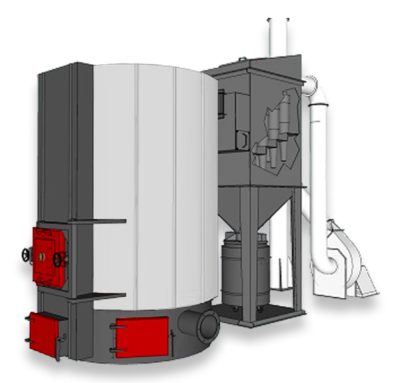

Vertical three-pass boiler for woodchip combustion

To download

HT MegaBio woodchip and pellet boiler – a high capacity boiler. It is equipped with a cylindrical combustion chamber made of refractory concrete. The chamber has a three-point controlled air intake with the division into primary and secondary air with autocontrol in cooperation with a Lambda probe.

The orientation of the secondary air inlets has allowed the flame to swirl, resulting in a better mixing of air and combustion gases. The combustion chamber made of refractory concrete burns fuels of considerable humidity. The most important feature of the boilers is the large surface area of the heat exchanger and large water capacity of the boiler (boiler buffer). This solution ensures a very stable water temperature and a high level of thermal safety for the entire system. Heat exchange takes place in a vertical, flame-shaped, steel heat exchanger which surrounds the furnace and combustion chamber. The three-pass flue gas circulation ensured a large heating surface of the boiler and high efficiency of heat exchange. This structure is the main advantage of HT Mega Bio by VENTIL boilers, it prevents dust from settling on the heating surface of the exchanger, which is of great importance during combustion. The use of a vertical flame heat exchanger in combination with a large heat exchange surface and large water capacity ensures the highest stability and thermal efficiency of the boiler and has a favourable impact on its longer service life.

The entire system is controlled by a central control panel which collects information from sensors, the fuel feed system, the combustion system, boiler water and possibly the entire heating system.

The global approach to system control translates into a high level of efficiency, safety and cost control, as the operation smoothly adapts to the heating requirements. Fully automated software, minimises the need for technical intervention and ensures reliable operation. Moreover, the control system is accessible via all kinds of mobile devices and the Internet.

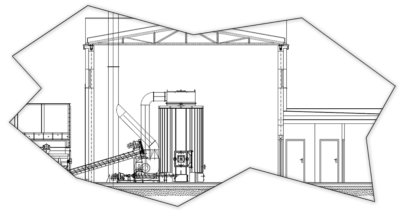

Example of a boiler house using a boiler with a stepped moving grate

| Rated power | kW | 580 | 870 | 1160 | 1450 | 1750 | 2320 | 3480 | 4640 | 5800 |

| Height | cm | 293 | 321 | 377 | 382 | 396 | 396 | 481 | 511 | 560 |

| Diameter | cm | 205 | 210 | 232 | 240 | 244 | 258 | 311 | 340 | 370 |

| Boiler room – min. Height | m | 5 | 5 | 5,5 | 5,5 | 6 | 6 | 7 | 8 | 8 |

| Heat exchanger surface area | m2 | 24 | 35 | 52 | 65 | 79 | 112 | 174 | 230 | 314 |

| Weight | kg | 4 200 | 4 600 | 4 730 | 7 900 | 5 200 | 10 800 | 13 000 | 29 500 | 34 500 |

| Water volume | dm3 | 2 000 | 3 100 | 4 550 | 5 200 | 5 600 | 6 900 | 9 400 | 13 000 | 18 000 |

| Maximum water temperature | 0C | 109 | 109 | 109 | 109 | 109 | 109 | 109 | 109 | 109 |

| Average heat capacity | % | 85 – 90 | 85 – 90 | 85 – 90 | 85 – 90 | 85 – 90 | 85 – 90 | 85 – 90 | 85 – 90 | 85 – 90 |

| Max. fuel consumption (pellets) | kg/h | 138-144 | 207-216 | 276-288 | 346-360 | 417-434 | 544-577 | 832-866 | 1108-1154 | 1380-1440 |

| HT MegaBIO by Ventil (HT MBV) 6500 – information available on request | ||||||||||

| HT MegaBIO by Ventil (HT MBV) 7000 – information available on request | ||||||||||