Pellet burner

with automatic sludge scraper, automation and feeder

Pellet burner

with automatic sludge scraper, automation and feederTo download

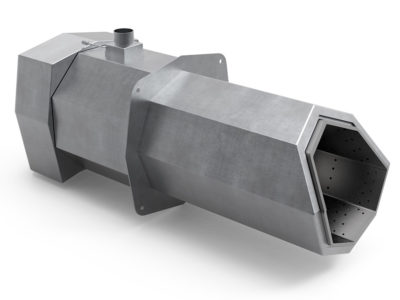

Pellet burner with automatic sludge scraper, automation and feeder ● Modern drop-in burner with igniter, optical sensor and internal feeder. ● The burner meets the requirements of the 5th class as per PN-EN 15270:2008. The innovative construction of the burner makes it possible to achieve the boiler’s flue gas emissions in the 5th class in accordance with the 303-5:2012 standard. ● An extensive distribution of primary and secondary air ensures the highest combustion quality. The Omega-type air curtain at the end of the burner pipe ensures optimum afterburning of outlet gases (Polish Patent Office No. Ru 069890). The combustion chamber in the shape of a regular octagon with a “V” shaped floor ensures high combustion efficiency when operating at reduced load – below 25% of nominal power (Polish Patent Office no. Ru 069889). The burner is equipped with a sludge scraper which is cyclically activated by the boiler automatics and prevents sludge accumulation on the combustion chamber (Polish Patent Office No. Ru 069889). Ergonomic construction of the burner reduces the time of servicing – cleaning, replacing the igniter, replacing sensors. The slanted placement of the igniter prevents it from getting dirty and wearing out prematurely. ● HT-Logic III algorithm is individually programmed for each boiler, which automatically selects operating parameters and modulates the burner output depending on the boiler temperature, thus reducing the amount of fuel consumed.

| Burner capacity [kW] | 14 | 20 | 28 | 35 | 45 | 55 | 70 | 90 | 135 | 170 | 230 | 280 | 350 | 450 | 550 |

| A – Overall length [mm] | 470 | 480 | 505 | 600 | 650 | 670 | 720 | 750 | 805 | 865 | 935 | 1036 | 1155 | 1192 | 1244 |

| B – Burner length [mm] | 160 | 170 | 195 | 230 | 280 | 300 | 310 | 330 | 385 | 415 | 470 | 515 | 571 | 608 | 661 |

| C – Hearth height [mm] | 133 | 150 | 170 | 182 | 194 | 211 | 219 | 232 | 279 | 303 | 325 | 336 | 370 | 392 | 445 |

| X – Horizontal fitting spacing [mm] | 240 | 240 | 240 | 235 | 235 | 235 | 235 | 235 | 280 | 280 | 315 | 315 | 353 | 415 | 415 |

| Y – Vertical fitting spacing [mm] | 185 | 185 | 185 | 209 | 220 | 220 | 220 | 220 | 280 | 280 | 315 | 315 | 353 | 415 | 415 |

| Z – Distance flange length [mm] | – | – | – | – | 80 | 80 | 80 | 206 | 206 | 231 | 231 | 206 | 231 | 256 |

-

Boiler pump

-

CH pump

-

DHW pump

-

Mixing valve pump

-

Mixing valve

-

Weather-compensated control

-

Thermostat

-

HT Logic II

-

Igniter

-

Alarm

-

WWW module

Moduły rozszerzające automatykę